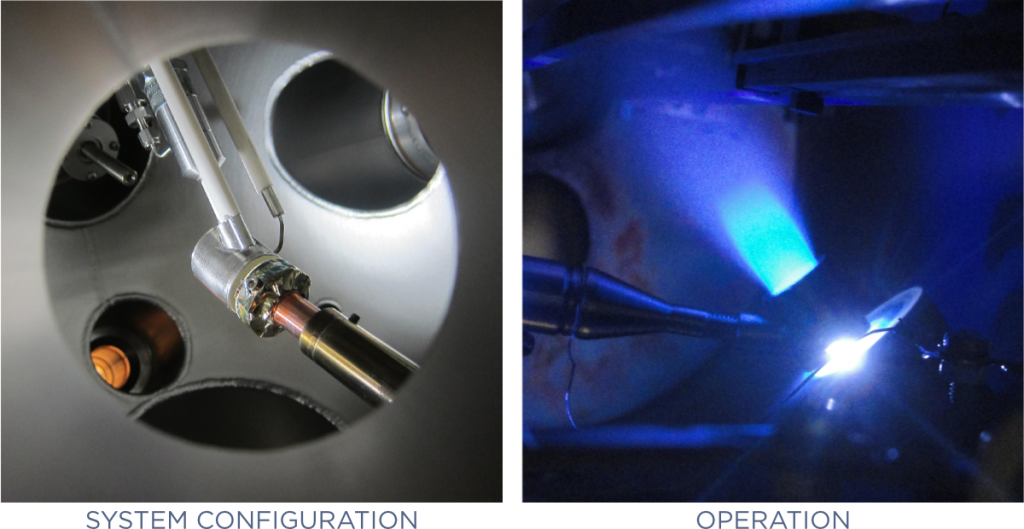

IONIZED JET DEPOSITION

Ionized Jet Deposition is a Physical Vacuum Deposition (PVD) technique based on pulsed electron ablation. IJD equipment, developed by Noivion, employs a special pulsed electron source able to generate in vacuum ultra-short and electric discharges in the MW range (peak). The discharge is supported by a gas jet and directed into a solid target generating a superficial explosion and consequent emission of very energetic material in the form of a plasma with the same composition as the target. The plasma emitted by the target produces a dense coating on any object it finds on its path with the same composition as the target or combined with a reactive background gas (reactive mode).

The IJD method is based on the ionization of a gas stream flowing through a metallic nozzle which serves simultaneously as the auxiliary electrode for the plasma discharge ignition. A high voltage pulse with an amplitude of up to 25kV and a duration of less than 1µs is applied to the cathode and, through a system of trigger and auxiliary electrodes, a causes strong ionization of the gas jet that brings about ablation of the target surface.

ADVANTAGES

IJD has unique characteristics delivering distinct advantages for a variety of applications.

- STOICHIOMETRY CONSERVATION

In porper conditions, IJD allows stoichiometry conservation just like in laser ablation systems (PLD). This means that the same composition of the target is transferred in the coating, allowing a relatively easy optimization of very complex materials like superconducting oxides (YBCO) or photoactive semiconductors (CIGS) that can be deposited in a single deposition step. - LOW TEMPERATURE PROCESSES

IJD films produced in the right conditions exhibit good crystalline quality even if deposited at room temperature thanks to the high plasma density and excitation. This allow to coat delicate substrates like plastic or semiconductor devices with hig quality films. - INDEPENDENT PARAMETERS

IJD offers mostly independent process variables allowing to explore a wide set of energies and conditions and fine tune even the more complex deposition processes. The main parameters are: acceleration voltage, gas pressure, sample-target distance, pulse repetition rate. - WIDE RANGE OF MATERIALS

Thanks to strong interaction of electrons with matter IJD can work with virtually any solid element: conductive, non conductive, transparent, ultra-hard. Even refractory metals or ultra hard ceramics are feasible with excellent control and reproducibility. - COMPETITIVE COST

IJD equipment provides more power and flexibility at a fraction of the cost of a pulsed laser deposition system. The possibility to coat large objects using small targets (10-30 mm diameter, disc shaped) offers a great cost optimization opportunity in the development of coatings made of rare and precious materials. - INDUSTRIAL

Quality coatings, robustness, competitive cost and high deposition rate make IJD a good opportunity for industrial manufacturing.