IJD and to some extent other Pulsed Electron Deposition (PED) devices show the ability to keep a target stoichiometry conserved under proper process conditions as one of its distinctive properties. At the ablation event all target material components are ejected simultaneously regardless of their evaporation enthalpy and transferred to the thin film maintaining the target compositional relations. This feature enables the manufacturing of thin film coatings composed of complex materials in a single process step.

IJD thanks to its superior power, robustness and scalability, compared to conventional PED sources, is a unique solution bringing such complex manufacturing processes to the industrial scale.

Deposition of high temperature complex superconductors like YBa2Cu3O7 (YBCO) by PED is one of the most studied processes and many papers on this topic are available in scientific literature [1,2]. Another very relevant application where stoichiometry is essential is CuInGaSe2 (CIGS) fabrication. CIGS is a complex photovoltaic semiconductor that stands out among the best performing photovoltaic materials (>21% single junction efficiency). CIGS thin films are usually manufactured by complex and expensive multi-step or co-deposition and thermal processes. The possibility to deposit this material in a single-stage process will lead to substantial cost reductions and process rationalization.

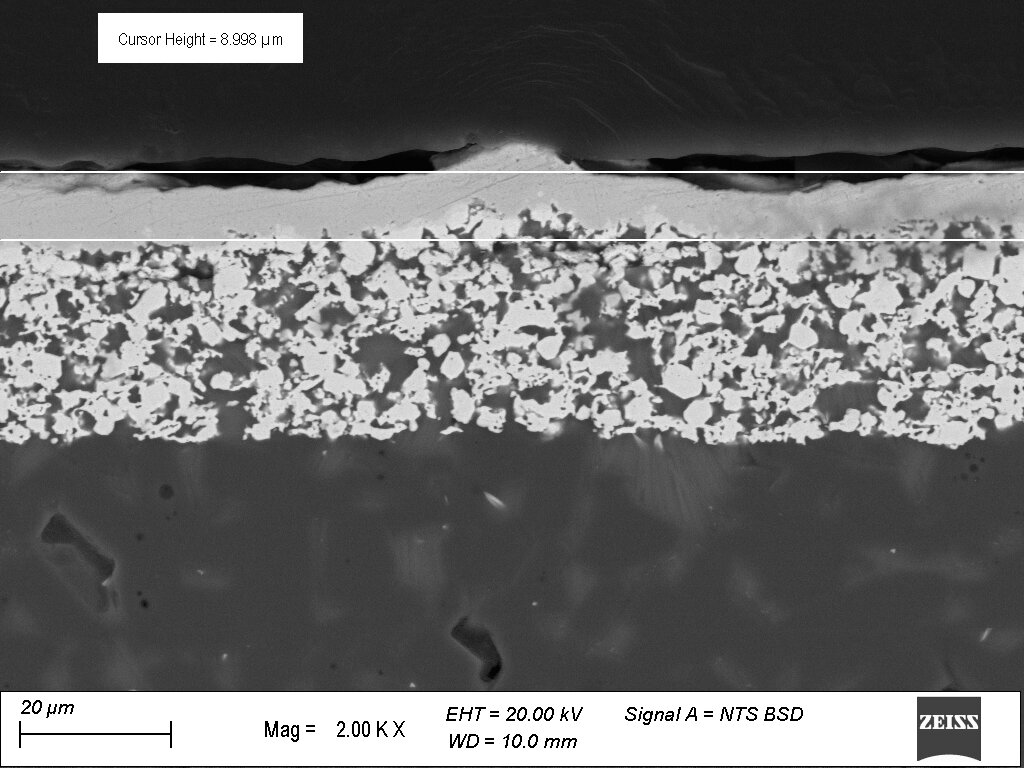

Thin film CIGS based solar cells prepared by PED have been studied extensively by some prominent research institutes leading to outstanding results. Solar cells based on the CIGS absorber layer deposited in the single-stage process have been produced at low temperatures achieving record efficiency exceeding 17% measured on non optimized devices [3].

Test trials confirmed the capacity of Noivion sources to transfer the complex composition to thin film coatings. Four Noivion PED sources have been installed on an in-line pilot deposition system in order to scale up the CIGS deposition process developed previously at the small (laboratory) scale.

Have been furthermore demonstrated that the CIGS stoichiometry transfer is directly related to the proper pulse intensity and pulse time profile promoting the non-thermal ablation of the target material and suppression of the target heat-up which otherwise may cause appearance of thermally evaporated non-stoichiometric phases.

Other complex multi-element processes include High Entropy Alloys like HfNbTiTaZr successfully deposited by IJD [4].

Noivion’s IJD source design take advantage of technical solutions developed according to the most advanced theoretical knowledge and empirical studies leading to the maximization of the amount of stoichiometrically ablated material and to the attenuation of general plasma discharge currents reducing harmful thermal evaporation to the minimum.

For more information on this application contact: info@noivion.com

[1] Strikovski et al (2003). Parameters that control pulsed electron beam ablation of materials and film deposition processes. Applied physics letters, 82(6), 853-855.

[2] Jakub Skočdopole et al (2021). Transport Coefficients in Y-Ba-Cu-O System for Ionized Jet Deposition Method. IEEE Applied Super Conductivity Tampa 2020, virtual conference

[3] Mazzer et al (2016) Progress on Low-Temperature Pulsed Electron Deposition of CuInGaSe2 Solar Cells. Energies, 9, 207.

[4] Skocdopole, Jakub & Cech, Jaroslav & Čapek, Jiří & Trojan, Karel & Kalvoda, Ladislav. (2023). Preparation of HfNbTiTaZr Thin Films by Ionized Jet Deposition Method. Crystals. 13. 580. 10.3390/cryst13040580.