Ionized Jet Deposition: a novel thin film coating technology. Learn how it works and why it is so flexible and effective over a wide range of applications.

Noivion at glance

We developed an environmentally sustainable and cost-effective state-of-art coating solution of refining the surface layers of your products, no matter what material you want to apply to what surface. See for yourself!

IONIZED JET DEPOSITION ADVANTAGES

IJD has unique characteristics delivering distinct advantages for a variety of applications.

-

VERSATILTY

-

COMPETITIVE COST

IJD equipment provides more power and flexibility at a fraction of the cost of a laser ablation system (up to 10 times lower CAPEX, 10-20 times smaller industrial size and 5 times more energy saving).

The possibility to coat large objects using small targets (10-30 mm diameter, disc shaped) offers a great cost optimization opportunity in the development of coatings made of rare and precious materials.

-

EASILY ADJUSTABLE PROCESSES

IJD offers mostly independent process variables allowing to explore a wide set of energies and conditions and fine tune even the more complex deposition processes.

The main parameters are: acceleration voltage, gas pressure, sample-target distance, pulse repetition rate.

-

WIDE RANGE OF APPLICATION

Thanks to strong interaction of electrons with materials IJD can work with virtually any solid material: conductive, non conductive, transparent, ultra-hard.

Even high melting point metals or ultra hard oxides are feasible with excellent control and reproducibility.

-

SUPERB IN LOW TEMPERATURE PROCESSES

IJD films produced in the right conditions exhibit good crystalline quality even if deposited at room temperature thanks to the high plasma density and excitation.

This allow to coat delicate substrates like plastic or semiconductor devices.

-

INDUSTRIAL READY

Quality coatings, scalability, robustness, low cost and high deposition rate make IJD a good opportunity for industrial manufacturing. Contact us to discuss your application.

-

STOICHIOMETRY CONSERVATION

With appropriate conditions, IJD allows stoichiometry conservation just like a laser ablation system. This means that the same composition of the target is reproduced in the coating, allowing a relatively easy optimization of very complex materials like superconducting oxides (YBCO) or photoactive semiconductors (CIGS) that can be deposited in a single step.

PROCESSES / APPLICATIONS

IJD and PLD, a comparison

Learn in this technical insights the similarities, differences and advantages of pulsed electron ablation techniques over light equivalent PLD

Two-dimensional layers

Transferring optoelectronic properties of 2D materials to a large-area thin film. A breakthrough towards the large-scale and affordable production of 2D-like materials.

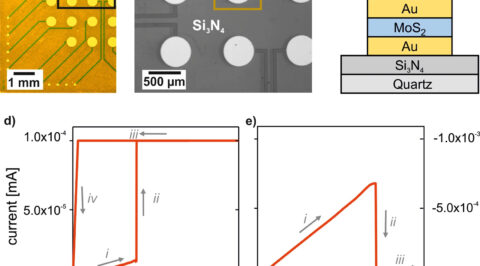

Molybdenum disulfide

IJD is emerging as cost-efficient and versatile thin-film fabrication technique for the fabrication of transition metal dichalcogenides thin films, such as MoS2.

Polymer thin films by IJD

Learn how IJD can be used to grow thin films made even by organic materials

Refractory metals

IJD is an effective solution for fast, efficient and controllable deposition of high melting point metals overcoming the limits of thermal and e-beam evaporators

Complex multi-element materials

IJD allows to deposit complex compounds preserving stoichiometric composition in a single coating step..

Plastic & Low thermal budget coatings

Pulsed and highly energetic plasma is the key to obtain quality coatings in low thermal budget processes. IJD enables coating on a wide range plastics and delicate substrates.

Biomimetic and antibacterial coatings

Osseointegration facilitation with antimicrobial properties in orthopeadic implants through IJD deposited coatings.

SnS and CdTe solar cells

R&D program at Verona University supported by CARITRO fundation to develop SnS solar cells by IJD technique